Product Solutions

Moxa 24+4G-port Gigabit modular managed Ethernet switch

Introduction

Access to clean water is one of the most important aspects of everyone's life. As communities grow, most water treatment plants scale their processes to collect and process water to meet the added demands of the area. Water treatment plants can be very large in size, and usually include land for storage tanks, processes, sediment ponds, maintenance buildings, and more. Water is collected from multiple wells, reservoirs and rivers, and then pumped to the water treatment plant, where it is treated and then delivered to customers. To monitor and control processes, utilities have traditionally relied on proprietary communication protocols, so the costs of installation, maintenance, and replacement of spare parts can be high.

The Aha Sa water plant in Korea is a major water treatment facility that has supported the local area's population and industrial growth for the last twenty years. The plant treats nearly all of the water used in the district using workstations interfaced with proprietary PLC control equipment to control pumps, valves, and other equipment that moves the water through the various treatment processes. The Aha Sa water plant wanted to upgrade their network infrastructure with state-of-the-art Ethernet technology that was readily available, cost-effective to integrate, and which could help collect data from numerous locations throughout the plant. An added benefit included Ethernet's ability to allow seamless upgrading for future and expansion.

Moxa Solution

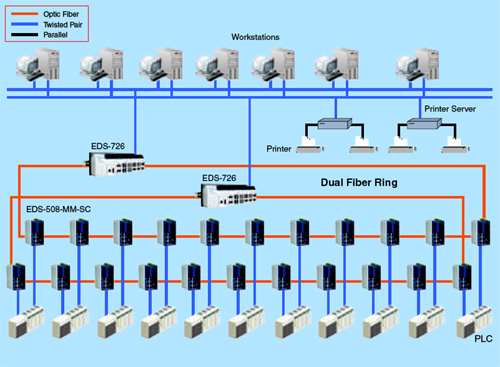

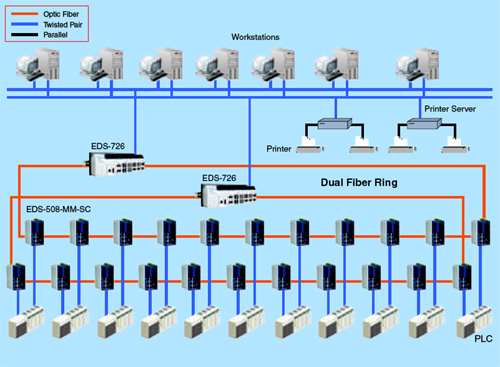

The Aha Sa plant chose the EDS-726 26-port managed Gigabit Ethernet switch because it provided multiple, easily-configured, modularized ports that support both traditional twisted pair copper and optical fiber for the long and short distances necessary to cover the entire plant site. In addition, the switch offered excellent reliability with its self-healing network recovery capability (under 300 ms) from broken LAN connections. The EDS-726 can handle all PLC data collection needs as well as central control and administrative support, effectively reducing cabling with a more efficient ring topology. The double media ring together with redundant node configurations for all critical processes significantly reduced possible system downtime and strengthened disaster recovery. The EDS-726 allowed the Aha Sa plant to move away from their proprietary protocols, lower component and maintenance costs, and add the Gigabit bandwidth necessary for additional monitoring and communications needs, such as video and voice. The fiber backbone was also more resistant to electromagnetic interference and transient voltages caused by the harsh weather conditions the plant sometimes experienced.

After the upgrade, operators could easily check the status of all processes from anywhere on the network. The ability to monitor storage tanks, levels and flow rates in wells and reservoirs, and quickly open or close valves during changes in demand, allows the plant to adjust flow to city water lines more efficiently and maintain a more stable system. It is easier to determine the cause and location of network malfunctions, and includes automatic notifications to operators and system controllers for alarm events. The system has simplified decision making by automating many processes, such as refilling multiple storage sites that were previously hard to monitor and control. The new system also makes it easier to store the results of sampling, schedules, and maintenance activities, and helps supply data to generate the diagnostic reports that are essential to any water treatment facility.

Why Moxa?

The EDS-726 supports long distance multi mode fiber.

The dual Turbo Ring feature makes configuration and management easier for double media redundancy and network node redundancy.

The EDS-726 provides more ports to connect devices to a central control room

Simplified networking

Reduced cabling costs

The EDS-726's modular design allows greater flexibility for configuration and expansion.