Product Solutions

Moxa 8-port Entry-level Managed Ethernet Switch with 3 Fiber Ports

Introduction

ONGC, Ltd., is a public sector Global Fortune 500 petroleum company based in Dehradun, India. The importance of the company to India's infrastructure is refl ected in the fact that ONGC contributes 77% of India's crude oil production, and 81% of the country's natural gas production. In fact, ONGC is the highest profit making corporation in India. ONGC maintains a vast influence over India's hydrocarbon industry. The company owns and operates more than 11,000 kilometers of pipelines across India, 3200 kilometers of which are undersea pipelines, and have active exploration projects in 26 sedimentary basins throughout India.

ONGC is involved in a wide range of activities in the petroleum industry. Principal activities include exploration, production, refi ning, transportation, and marketing crude oil, natural gas, liquefi ed petroleum gas, natural gas, liquid ethane/propane, and related products. Recently, ONGC entrusted ABB Bangalore for services that include site survey, system design, engineering, supply, installation, and a 6-year maintenance contract for 45 offshore and onshore drilling stations across India. The most important accomplishment of this project is that ONGC will be able to manage its manufacturing and assets remotely from the enterprise's central control room.

Moxa Solution

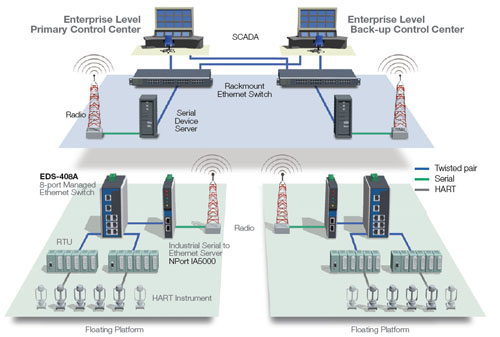

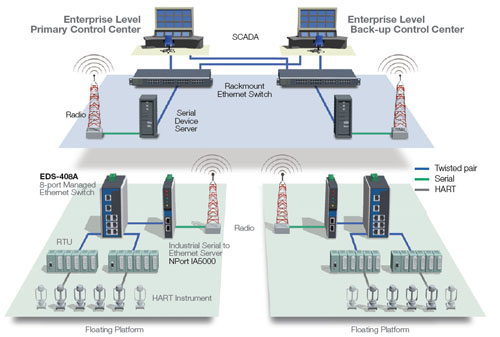

The project involves creating systems that integrate real-time information from production facilities with asset data, and then transmitting the information to ONGC's corporate data center to manage the performance of the 45 offshore and onshore drilling stations. ABB Bangalore achieved this feat by integrating different SCADA systems into an enterprise-wide SCADA network for managing oil and gas drilling platforms. The enterprise's control room includes several SCADA servers that form a control terminal for the remote control and monitoring of the drilling platforms. A communication network was set up to link the enterprisewide control room with the 45 ONGC-owned drilling stations for the purpose of collecting data remotely. The system adopted a TDMA radio to form a wireless network between the control level network and the servers in the enterprise control room.

Each drilling platform uses HART instruments connected to redundant RTUs (Remote Terminal Units) to control drilling facilities on the fl oating platforms in the field. The RTUs are equipped with Ethernet ports to transmit data over an Ethernet network formed by Moxa's EDS-408A series industrial managed Ethernet switches. The EDS-408A's capability for high-bandwidth, real-time transmission helps ensure efficient communication between the fi eld operation facilities and control station. With a solid 5-year warranty, high MTBF value, and extended operating temperature, the EDS-408A industrial managed Ethernet switch is especially well suited for applications in harsh industrial environments. In addition, the EDS-408A series switches are DNV and Class 1, Div. 2/Zone 2 certifi ed to ensure reliable operation in offshore oil and gas fields, such as ONGC's drilling platforms in India.

Why Moxa?

Moxa's managed Ethernet switches are ABB IIT,UL508, DNV, and Class 1, Div. 2/Zone 2 certified, making them a natural fi t for offshore oil and gas applications.

The redundant power inputs long MTBF, and 5-year warranty of Moxa's Ethernet switches make the network extra reliable.

The SNMP V1/V2C/V3 and RMON feature supported by Moxa's managed EDS-series switches make it easier for engineers to monitor and control their devices over the network.