Product Solutions

Moxa Ethernet Micro RTU Controller with 4 analog inputs and 12 configurable DIOs

Introduction

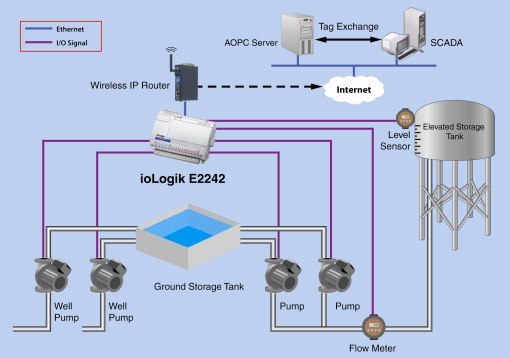

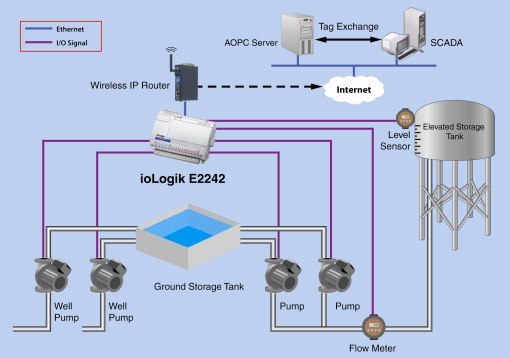

As populations expand, water pumping stations are commonly built to satisfy the demand for clean water by extracting and sterilizing water from underground wells. A water pumping station is a complex interlocking system comprised of many different distributed devices, including sterilization equipment, ground storage tanks, elevated storage tanks, well pumps, and booster pumps. Data acquisition and control systems are used to manage this multi-step, multi-level water pumping and sterilization process.

System Requirements

Remote wireless data acquisition to SCADA

Real-time data acquisition

Local control logic that reads analog inputs and triggers digital outputs

Moxa Solution

Two sets of ioLogik E2242 units are deployed in this application. The ioLogik E2242 is a 4AI and 12 DIO RTU that offers precisely the connectivity options needed for a water pumping station.

One set of E2242s are used to control the well pumps that pump water out of underground wells to the ground storage tank. One analog channel of the E2242 is used to monitor the tank water level. Meanwhile, one of the digital ports is used for pump control. The E2242 can be effortlessly configured using simple Click&Go™ technology to turn on the pumps when the analog channel reports low water levels in the ground storage tank, and to turn off the pumps when the tank is full to prevent an overflow. Additional digital inputs are used to monitor the pump status and power supply status.

The second set of E2242s is used on the other side of the system to control the booster pumps that pump water from the ground storage tank to the elevated storage tank. These E2242s operate in a similar role, controlling booster pump operations based on the current water level of the elevated storage tank. Additionally, an extra analog channel is used to monitor the flow meter measuring the total flow in the pipes connecting the ground storage tank to the elevated storage tank.

Pumping stations are located where water wells can be found, not where it is convenient. Remote pumping stations often have no landline connections available onsite, and must use GPRS communications for data transfer. However, the GPRS network has limited bandwidth, so polling data acquisition architectures with a constant query-and-response between host and client are not feasible. Using Moxa's Active OPC Server software and one of Moxa's wireless IP routers, the E2242 can intelligently and actively "push" instantaneous pump and power status alarms to the central SCADA system without consuming expensive GPRS traffic.

Product Applied

ioLogik E2242

Versatile 4AI/12DIO design is optimal for small pumping stations

Active OPC Server provides seamless integration with SCADA

Push-based tag updates to SCADA enables real-time monitoring and conserves network bandwidth

Why Moxa?

Auto tag generation reduces how much time is required to create tags on the OPC Server

Combined Analog and Digital signal collection in one module saves costs

Simple menu-driven programming-free Click&Go™ configuration saves substantial deployment and development costs and time